Bio-inLine® Biofilm Reactor

A Comprehensive Solution for Fluid Distribution System Studies

The Bio-inLine® Biofilm Reactor (IBR) offers a sophisticated platform for the growth and testing of biofilms, simulating conditions commonly found in fluid distribution and food processing systems. It is a versatile system designed to meet specific research requirements.

Versatile Applications

The IBR is uniquely designed to simulate the conditions prevalent in common fluid-based systems. Researchers can easily install the reactor within fluid piping systems, enabling on-demand biofilm testing within the system itself. This versatility allows for a broad spectrum of research applications and ensures that studies align with real-world scenarios, enhancing their relevance and impact.

Enhanced Sampling Ease

The IBR is meticulously crafted with modifications that improve the ease of sampling. Researchers can access and collect biofilm samples with precision and convenience, ensuring that experiments run smoothly and without complications.

Unlock the potential of the Bio-inLine® Biofilm Reactor for your fluid distribution and food processing system research and development projects.

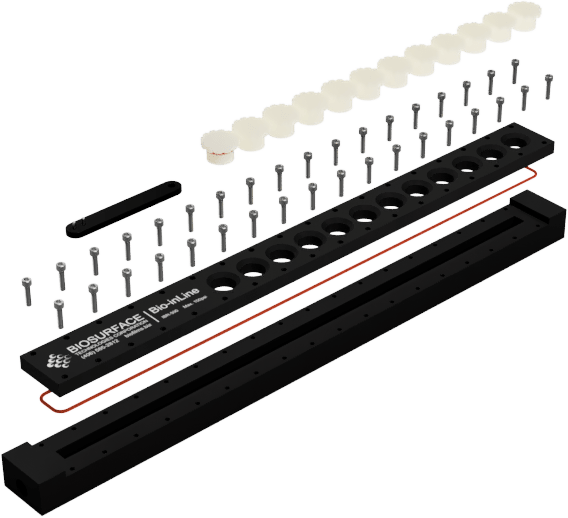

IBR 500-PET

The standard IBR includes coupon holder plugs, PET coupons (alternate coupon materials available upon request), and a coupon removal tool.

IBR 500-10

These nylon Coupon Holder Plugs hold a half-inch standard disc coupon. Twelve are included with each IBR.

Reactor Components

- Nylon Coupon Holder Plugs: The IBR consists of twelve (12) nylon coupon holder plugs threaded into a black PET or stainless steel lid. Each of these plugs is engineered to accommodate a 1/2-inch (12.7 mm) diameter coupon. In total, the IBR holds 12 coupons per reactor, using the same coupons as those used in the CDC and Rotating Disk Biofilm Reactors. This design ensures compatibility with established research methodologies and provides flexibility for a wide range of experiments.

- Lid and Body Construction: The lid, along with coupon holders and coupons, is securely mounted to a black PET or stainless steel body. This body contains a half-inch channel designed to mimic standard half-inch fluid pipe. The design mirrors the characteristics of actual fluid distribution systems, enabling realistic and highly relevant biofilm testing.

- Silicone Rubber O-Rings: The entire chamber is sealed with the assistance of silicone rubber O-rings, ensuring a watertight and secure environment for biofilm growth and testing. This feature is crucial for maintaining the integrity of experiments and preventing fluid leakage.

- Fluid Pressure Capacity: The IBR is engineered to withstand up to 80 psi of fluid pressure, making it suitable for research projects that require controlled fluid pressure conditions.

Modified Robbins Device (mRD) Inspiration

The IBR is designed and fabricated with the original modified Robbins Device (mRD) in mind, paying homage to a foundation in biofilm research. However, it incorporates innovative modifications to enhance sampling procedures and overall usability.

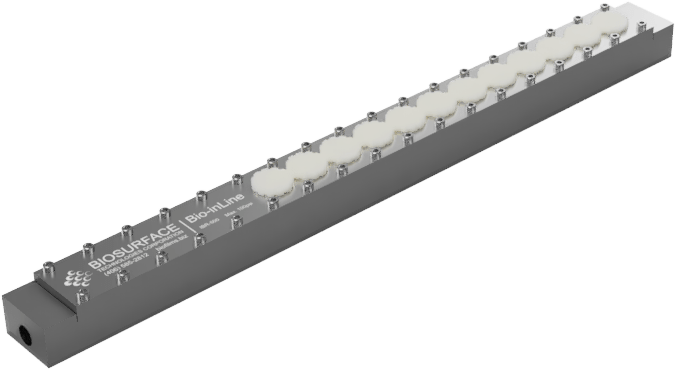

IBR 500-316

The 316 stainless steel version of this reactor offers a more robust alternative, for use in industrial situations, and tougher chemistries or temperatures.