About BioSurface Technologies

(Founder and CEO Bryan Warwood setting up some of the original Biofilm Annular Reactors in 1994)

Some Product Examples:

Drip Flow Biofilm Reactor®

Model DFR 110-4PET (pictured above) is one of our more popular biofilm reactors. These robust reactors offer completely separate channels for growing a wide variety of microbes on a surface with an air-liquid interface.

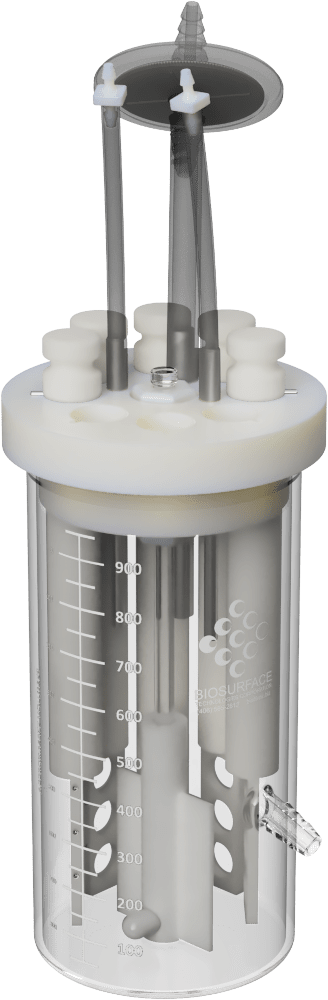

CDC Biofilm Reactor®

Model CBR 90-2 (pictured above) has become a globally-recognized powerhouse biofilm reactor. This reactor, designed in conjunction with the Center for Disease Control and Prevention, provides twenty-four (24) replicates per experiment which can be used for all kinds of studies, including antimicrobial testing.

Treatment Imaging Flow Cell

The Treatment Imaging Flow Cell (FC 310) was designed due to a need to easily image coupons from the CDC Biofilm Reactor® during treatment. The flow cell holds a single coupon, and can be used either in conjunction with a CBR or completely on it’s own.