Rotating Disk Biofilm Reactor

Unlock the Potential of the Rotating Disk Biofilm Reactor for Your Biofilm Studies

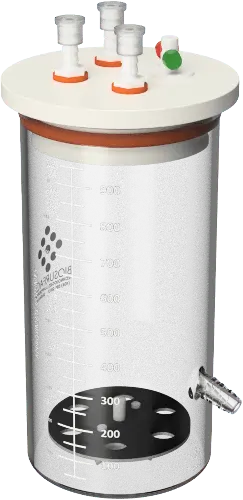

Explore the advanced capabilities of the Rotating Disk Biofilm Reactor, a sophisticated tool meticulously engineered for biofilm research under low to intermediate shear conditions. Designed with a teflon and viton disk housing six 12.7 mm (0.5 in) diameter coupons, this reactor allows for versatile experimentation with various machinable materials. The disk, featuring recesses for coupons and a star magnet for rotation, is placed in a 1000 ml glass reactor vessel with a working volume of approximately 250ml. As the disk rotates in the vessel, liquid growth media/biocide/etc. is circulated, creating optimal conditions for biofilm formation.

Versatile Applications

With the Rotating Disk Biofilm Reactor, you have the power to explore and innovate in diverse areas of biofilm research:

- Biofilm Formation Studies: Investigate the kinetics of biofilm rate processes, including nutrient uptake, growth rate, and biofilm removal.

- Coupon Material Variability: Choose from a variety of coupon materials, including plastics, metals, and ceramics, to tailor your experiments to specific industry requirements.

- Seamless Sampling: Aseptically remove the entire disk for efficient sampling, utilizing the provided tool to remove coupons for further study or imaging using microscopy.

- Biofilm Research Efficiency: Experience a compact construction with minimum space requirements, allowing for controlled fluid shear independent of bulk residence time.

DK20 Rotating Disk Biofilm Reactor

Holds 6 x RD 128 disk coupons

Autoclavable and Reusable Components

The components of the Rotating Disk Biofilm Reactor are designed for efficiency and sustainability. The teflon and viton disk, glass reactor vessel, and all associated components are autoclavable and reusable, ensuring consistent, high-quality testing throughout your research journey.

Choose the Rotating Disk Biofilm Reactor to elevate your biofilm research capabilities. With its precision design, versatility, and efficient operation, this reactor is the ideal choice for scientists and researchers seeking to understand and control biofilm growth. Accelerate your path to innovation in biofilm studies and experience the difference today.

Replacement Parts

All Rotating Disk Reactor components and parts are available for purchase individually. Check out our full list of replacement parts:

0.5 in. Diameter Sample Coupon

More than 40 materials are already available, and we are always willing to try new materials for specialty projects! Check out our full list of available materials and pricing:

ASTM Standard Method using the Rotating Disk Reactor:

Standard Test Method for Quantification of Pseudomonas aeruginosa Biofilm Grown with Medium Shear and Continuous Flow Using Rotating Disk Reactor: