Drip Flow Biofilm Reactor®

Unlock the Potential of the Drip Flow Biofilm Reactor® for Your Research and Development Needs

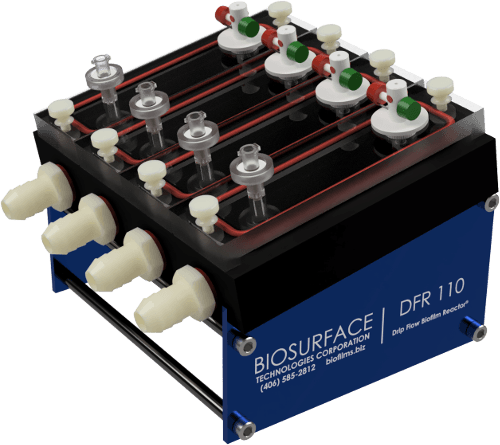

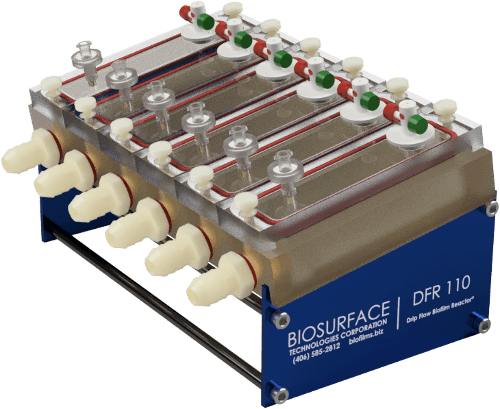

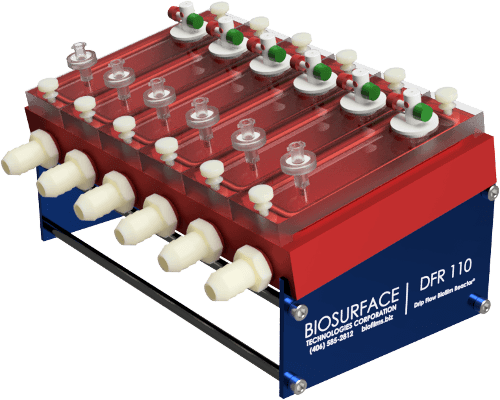

The Drip Flow Biofilm Reactor® is a versatile system designed for various research applications. It consists of four (4) or six (6) parallel test channels, each capable of holding one (1) standard glass microscope slide-sized coupon or a length of catheter or stint (after custom modification upon request).

Efficient, Precise Design, and Reusability

Growth media is provided by dripping over the coupon or catheter surface, creating low shear conditions and a short residence time (2 minutes). For catheter and stint studies, an alternate end media port allows flow within the catheter or stint. Media flows via gravity to ensure a very low shear condition. The Drip Flow Biofilm Reactor® is designed for ease of use and reusability. It can be conveniently autoclaved and reused, ensuring consistent, high-quality testing throughout your research journey.

Experience the difference and accelerate your path to innovation and discovery with the Drip Flow Biofilm Reactor®.

DFR 110-4PET

4-channel PET (polyethylene terephthalate) Drip Flow Biofilm Reactor® with Reactor Support Stands

DFR 110-6

6-channel polysulfone Drip Flow Biofilm Reactor® with Reactor Support Stands

Applications for Comprehensive Research:

- Microsensor Monitoring: The Drip Flow Biofilm Reactor® offers an ideal environment for precise microsensor monitoring, enabling you to collect highly accurate data for your research. This is especially valuable when you need to closely examine and understand microenvironmental conditions within biofilms.

- General Biofilm Studies: For a wide range of biofilm research, the Drip Flow Biofilm Reactor® provides a controlled and consistent environment to conduct experiments and investigations. Whether you’re studying biofilm formation, growth dynamics, or the impact of environmental factors, this system supports your needs with flexibility and precision.

- Biofilm Cryosectioning Samples: The Drip Flow Biofilm Reactor® streamlines the preparation of biofilm cryosectioning samples. This simplifies the process for in-depth analysis and examination of biofilms, making it easier to study the structural and chemical composition of biofilm communities.

- High Biomass Production: When your research demands a substantial amount of biofilm biomass, this system supports high biomass production. You can be confident that your experiments are well-equipped with an ample supply of biofilm samples, ensuring you have enough material to conduct extensive and thorough studies.

- Dental and Medical Material Evaluations: The Drip Flow Biofilm Reactor® is a valuable tool for assessing the performance, safety, and efficacy of dental and medical materials. Whether you’re evaluating the biocompatibility of dental implants or the antimicrobial properties of medical coatings, this system provides the controlled conditions necessary for thorough material testing.

- Indwelling Medical Device Evaluations: For the development of advanced medical technologies, assessing the performance and safety of indwelling medical devices is crucial. The Drip Flow Biofilm Reactor® offers a controlled platform for such evaluations, ensuring that these devices meet the highest standards of reliability and patient well-being.

Customization for Your Unique Needs:

Custom modifications are available upon request, allowing you to tailor your experiments to specific research requirements. Choose from a wide variety of coupon materials, including plastics, metals, and ceramics, to match your experiments to specific industry requirements. Additionally, custom modifications can be made for catheter and stint studies, offering flexibility for research in the medical field.

DFR 110-6AL

6-channel red-anodized aluminum Drip Flow Biofilm Reactor® with Reactor Support Stands

Watch instructional videos on the DFR (Produced by the Center for Biofilm Engineering at MSU):

DFR Material Selection

Polysulfone is the original yellowish-clear plastic. It is autoclavable and resistant to acidic chemistries, but very fragile (crystalline plastic that easily cracks or crazes).

Black Polyethylene Terephthalate (PET) has similar chemical resistance as Polysulfone but is much more resistant to physical and thermal stress (amorphous plastic without fracture planes). It is also a slightly less expensive option. PET is an opaque autoclavable thermoplastic.

Both plastic options will eventually decay from repeated autoclave cycles.

Anodized Aluminum is very resistant to thermal and physical stress. The anodized coating is very thin and can be scratched easily. Once the anodized coating is removed, the underlying aluminum metal is very reactive in salt-containing solutions (growth media). The anodized coating will decay after repeated exposure to acidic conditions. The coating can be reapplied by reanodizing.

Replacement Parts

All Drip Flow Biofilm Reactor components and parts are available for purchase individually. Check out our full list of replacement parts:

Slide Sample Coupon

Many materials are already available, and we are always willing to try new materials for specialty projects! Check out our full list of available materials and pricing:

ASTM Standard Method using the Drip Flow Biofilm Reactor

Standard Test Method for Quantification of Pseudomonas aeruginosa Biofilm Grown Using Drip Flow Biofilm Reactor® with Low Shear and Continuous Flow: