Biofilm Reactors

BioSurface Technologies offers a variety of Biofilm Reactors, each designed with specific capabilities and operations to cater to diverse and unique research needs and requirements. These versatile systems provide you with the tools necessary for your research and development projects. Experience the difference today and accelerate your path to innovation and discovery.

Reactor Capabilities

-

Reproducible Biofilm Growth: Our biofilm reactors are engineered to provide highly reproducible biofilm growth conditions, ensuring consistent and reliable research results.

-

Multiple Samples: Our biofilm reactors can accommodate multiple samples, streamlining your research process and allowing for comparative studies or investigations across different materials or conditions.

-

Diverse Coupon Materials: BioSurface Technologies offers a wide range of coupon materials, including plastics, metals, and ceramics, allowing you to select the model that matches your research requirements.

-

Versatility for Varied Shear and Operational Conditions: Our biofilm reactors are available in various shapes and sizes, each designed to operate under specific shear and operational conditions. This adaptability ensures that you can select the model that best suits your research goals.

-

Suitable for Time-Course Studies: Some of our biofilm reactors are ideal for time-course experiments, providing you with the tools to gain insights into biofilm dynamics.

-

Cited in ASTM and USEPA Standard Methods: Several of our biofilm reactors are referenced in ASTM and USEPA standard methods, aligning your research with established standards and ensuring consistency.

-

Autoclavable and Reusable: All of our biofilm reactors are autoclavable and reusable, offering sustainability and cost-effectiveness for your research.

Reactor Operations

-

Analyze Biofilm Formation on Multiple Materials: Our biofilm reactors enable you to assess biofilm formation on various materials, making them suitable for a wide range of research applications.

-

Statistically Relevant Testing: Achieving statistically relevant results is crucial in scientific research. Our biofilm reactors are designed to support statistically robust testing, ensuring meaningful and reliable data.

-

Suitable for Biocide and Antibiotic Development and Testing: Our biofilm reactors are well-suited for the development and testing of biocides and antibiotics, contributing to the development of breakthrough solutions to combat microbial threats.

-

Variable Shear Independent of Flow: Some of our biofilm reactors offer control over shear independent of flow, allowing you to investigate the impact of shear variations on biofilm behavior.

-

Continuous-Flow Through Systems: Continuous-flow systems are essential for studies that require a consistent flow of growth media. Our biofilm reactors are designed to provide this seamless flow.

-

Suitable for Aerobic and Anaerobic Cultures: We offer biofilm reactors that are adaptable to both aerobic and anaerobic cultures, offering flexibility for your diverse research needs.

BioSurface Technologies’ Reactors:

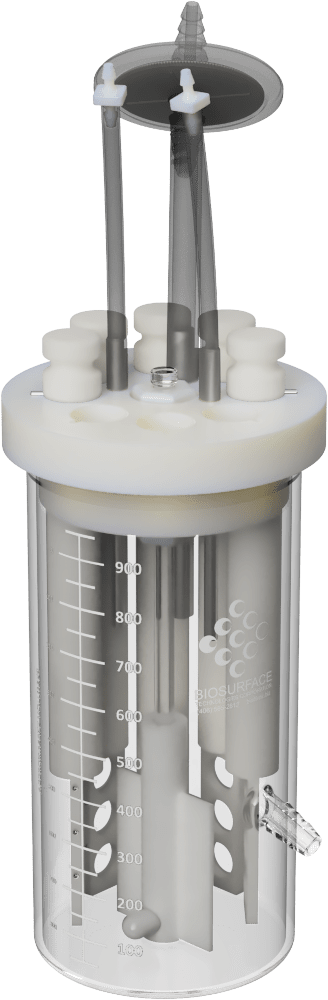

CDC Biofilm Reactor®

The CDC Biofilm Reactor® features eight polypropylene coupon holder rods suspended from a UHMW-polyethylene ported lid. Each holder rod can accommodate three 1/2-inch (12.7 mm) diameter coupons. These components are assembled within a 1-liter glass vessel, complete with a side-arm discharge port. Liquid growth media, biocides, and more can be efficiently circulated through the vessel, with mixing and shear generated by a magnetic stir bar/vane rotated by a magnetic stir plate.

(Standardized Methods: ASTM E2562, ASTM E3161, ASTM E2871, MB-19, and MB-20)

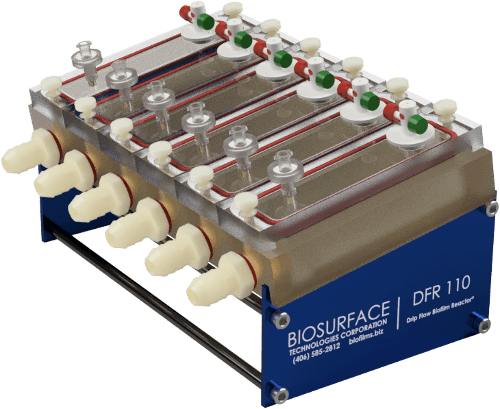

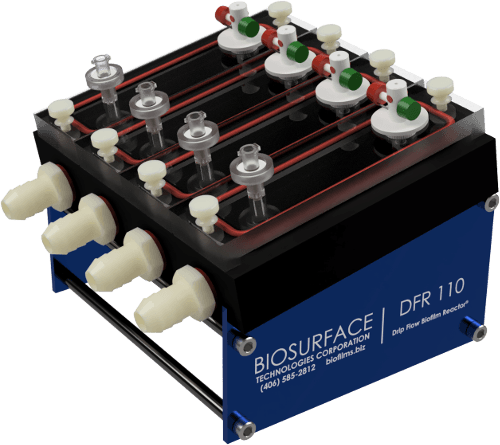

Drip Flow Biofilm Reactor®

The Drip Flow Biofilm Reactor® is a versatile system designed for various research applications. It consists of four (4) or six (6) parallel test channels, each capable of holding one (1) standard glass microscope slide-sized coupon or a length of catheter or stint (after custom modification upon request).

(Standardized Method: ASTM E2647)

Biofilm Annular Reactor

The BAR consists of two concentric cylinders: a stationary outer cylinder and a rotating inner cylinder. Process fluid moves in the region between the cylinders with biofilms accumulating on the internal surfaces. Rotational speed (30 to 500 RPM) is controlled by a variable-speed DC motor (100 to 240 VAC). Twenty removable slides are flush mounted on the internal, rotating cylinder. Slides (coupons) for obtaining deposit samples can be constructed from most relevant materials.

Rotating Disk Biofilm Reactor

Explore the advanced capabilities of the Rotating Disk Biofilm Reactor, a sophisticated tool meticulously engineered for biofilm research under low to intermediate shear conditions. Designed with a PTFE and Viton disk housing six 12.7 mm (0.5 in) diameter coupons, this reactor allows for versatile experimentation with various machinable materials. The disk, featuring recesses for coupons and a star magnet for rotation, is placed in a 1000 ml glass reactor vessel with a working volume of approximately 250ml. As the disk rotates in the vessel, liquid growth media/biocide/etc. is circulated, creating optimal conditions for biofilm formation.

(Standardized Method: ASTM E2196)

Bio-inLine® Biofilm Reactor

The IBR is uniquely designed to simulate the conditions prevalent in common fluid-based systems. Researchers can easily install the reactor within fluid piping systems, enabling on-demand biofilm testing within the system itself. This versatility allows for a broad spectrum of research applications and ensures that studies align with real-world scenarios, enhancing their relevance and impact.

Industrial Surfaces Biofilm Reactor

The Industrial Surfaces Biofilm Reactor (ISBR) is a sophisticated bench-top biofilm growth chamber meticulously engineered to cultivate biofilm under low shear, ensure high gas transfer, and facilitate intermittent wetting. Sample slides are continuously or periodically wetted through a fluid distribution port in the reactor, creating an environment conducive to robust biofilm formation. The ISBR serves as a valuable tool for studying both dry and wet biofilms, providing a comprehensive platform for versatile research.

Choose Your Reactor by Research Area

Dental: Biofilms play a significant role in dental research, affecting oral health and treatment efficacy. Common species like Streptococcus mutans and Porphyromonas gingivalis contribute to dental caries and periodontal diseases. Biofilm reactors such as the CDC Biofilm Reactor® and Rotating Disk Biofilm Reactor are ideal for simulating oral conditions and studying biofilm formation on dental materials.

Medical: In medical settings, biofilms pose challenges by forming on medical devices and causing infections. Species like Staphylococcus aureus and Pseudomonas aeruginosa are often associated with medical biofilms. Biofilm reactors such as the Drip Flow Biofilm Reactor® and CDC Biofilm Reactor® provide platforms for studying biofilm growth on medical surfaces and evaluating antimicrobial treatments.

Food Safety and Food Processing: Biofilms impact food safety by contaminating equipment and surfaces in food processing facilities. Species like Listeria monocytogenes and Salmonella enterica are common in food-related biofilms. The Industrial Surfaces Biofilm Reactor and the Bio-inLine® Biofilm Reactor are suitable for studying biofilm formation on food-contact surfaces and developing effective cleaning and sanitation strategies.

Drinking Water Distribution and Waste Water Processing: In the drinking water industry, biofilms in distribution systems can lead to water quality issues. Species like Legionella pneumophila and Mycobacterium avium are concerning in drinking water biofilms. The Biofilm Annular Reactor (BAR) and Bio-inLine® Biofilm Reactor are valuable tools for studying biofilm growth in water distribution systems and assessing disinfection strategies.

Biofilms and Bacterial Ecology: In bacterial ecology, biofilms play a crucial role in microbial communities and ecosystem dynamics. Species diversity and interactions shape biofilm structures and functions. Biofilm reactors such as the Biofilm Annular Reactor (BAR) and CDC Biofilm Reactor® are instrumental in studying biofilm ecology, microbial interactions, and community dynamics.

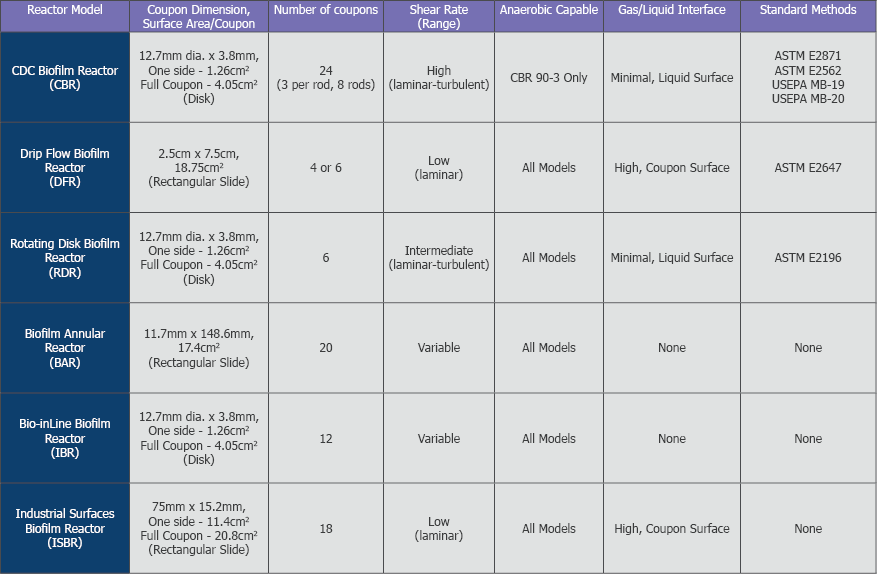

BioSurface Technologies’ Biofilm Reactors at a Glance